From FT

This content was paid for by Mitsui O.S.K.

Lines and produced in partnership with the Financial Times Commercial department.

The SS Savannah, the first steamship to cross the Atlantic in 1819, was a hybrid vessel.

While driven chiefly by the wind in its sails, Savannah also used an auxiliary steam engine and paddlewheels for part of its journey.

Since this early feat of engineering during the industrial era, fossil fuels have gradually replaced wind as the dominant force in maritime propulsion.

Coal-powered steamships rose in the 19th century, followed by oil-fuelled marine diesel engines in the 20th century.

Today, the majority of global shipping relies on heavy fuel oil, and the sector is responsible for around 2 per cent of all energy-related carbon dioxide emissions, according to the International Energy Agency.

Now, two centuries after Savannah’s voyage, shipping is embracing hybrid propulsion systems once again.

Various wind-assisted technologies are being developed and tested, including kites, rotor sails, rigs, vertical wings and wind-turbine engines, all designed to work alongside conventional ships.

Lines and produced in partnership with the Financial Times Commercial department.

The SS Savannah, the first steamship to cross the Atlantic in 1819, was a hybrid vessel.

While driven chiefly by the wind in its sails, Savannah also used an auxiliary steam engine and paddlewheels for part of its journey.

Since this early feat of engineering during the industrial era, fossil fuels have gradually replaced wind as the dominant force in maritime propulsion.

Coal-powered steamships rose in the 19th century, followed by oil-fuelled marine diesel engines in the 20th century.

Today, the majority of global shipping relies on heavy fuel oil, and the sector is responsible for around 2 per cent of all energy-related carbon dioxide emissions, according to the International Energy Agency.

Now, two centuries after Savannah’s voyage, shipping is embracing hybrid propulsion systems once again.

Various wind-assisted technologies are being developed and tested, including kites, rotor sails, rigs, vertical wings and wind-turbine engines, all designed to work alongside conventional ships.

Mitsui O.S.K. Lines (MOL), one of the world’s largest shipping companies, announced that it is building the world’s first liquefied natural gas carrier equipped with its Wind Challenger technology, in partnership with Chevron Shipping Company, a subsidiary of US oil giant Chevron.

This innovative system uses rigid telescopic sails to harness wind power to propel the ship, aiming to reduce both fuel consumption and greenhouse gas emissions.

This development follows two Wind Challenger-equipped ships - Shofu Maru and Green Winds, that were built in 2022 and earlier this year.

“Achieving greenhouse gas reduction in the maritime transport of LNG, which is increasingly in demand worldwide as a transition fuel, is a very important mission for us,” says Takeshi Hashimoto, president and chief executive of Mitsui O.S.K. Lines.

“Installing Wind Challengers to both existing and upcoming vessels will undoubtedly be a significant milestone towards our goal of achieving net-zero greenhouse gas emissions by 2050.”

The Wind Challenger-equipped LNG carrier

Innovation like this is crucial as the shipping industry faces increasing pressure from regulators and customers to decarbonise.

Since January 2024, ships docking in European ports must pay levies under the European Union’s Emissions Trading System, with some estimates suggesting ships could face a combined carbon emissions bill of $3.6bn for the year.

Major retailers such as Amazon and Ikea are offering tenders for shipping services powered by cleaner fuels that can slash emissions by over 90 per cent.

Meanwhile, member states of the International Maritime Organization, the UN agency that governs international shipping, have committed to reaching net zero emissions for the sector by around 2050.

Source: IMO’s work to cut GHG emissions from ships

Blowing in the wind

Among the various options for reducing shipping’s greenhouse gas emissions – such as alternative fuels, hull-cleaning robots and digital solutions to optimise operations – wind power remains a particularly attractive option.

Among the various options for reducing shipping’s greenhouse gas emissions – such as alternative fuels, hull-cleaning robots and digital solutions to optimise operations – wind power remains a particularly attractive option.

However, wind-assisted propulsion for large vessels faces challenges, including a shortage of funding, industry concerns over performance, safety and operational impacts on ships, as well as the high costs of installing such systems across diverse fleets.

MOL hopes the Wind Challenger system will address these issues.

The system was developed in collaboration with Japanese shipbuilder Oshima Shipbuilding Co., ensuring that it meets the shipping industry’s safety and durability standards.

It uses sails constructed using a large volume of fibre-reinforced plastics (FBP), not typically used as structural material on ships, to reduce sail weight.

The sails can be extended and retracted to keep the ship stable in rough seas, while features such as a navigation bridge and a lookout station improve visibility for the crew.

“Unlike competing technologies, our Wind Challenger system not only generates propulsion from tailwinds but also produces lift from headwinds, enhancing sailing efficiency,” says MOL.

“While, like all wind-assist technologies, its effectiveness varies depending on wind direction, its versatility allows for installation on new vessels and retrofitting on existing ships.

Multiple vertical sails can also be added to a single vessel to boost fuel efficiency.”

Wind Challenger has already proven itself in commercial operations.

The system has been installed on two MOL vessels – the Shofu Maru in 2022 and Green Winds in 2024 – with more installations planned for the future.

Shofu Maruachieved a 7 to 16 per cent reduction in greenhouse gas emissions, depending on route and conditions, during seven round-trip voyages from Japan to locations such as Australia, Indonesia and North America.

MOL expects Green Winds to deliver similar results.

To date, the company has visited over 30 locations globally, engaging with terminals, coast guards, port authorities and pilot associations to ensure safe operations in coastal and harbour environments.

MOL plans to install the system on 25 vessels by 2030 by equipping new vessels and retrofitting old ones, increasing to 80 by 2035.

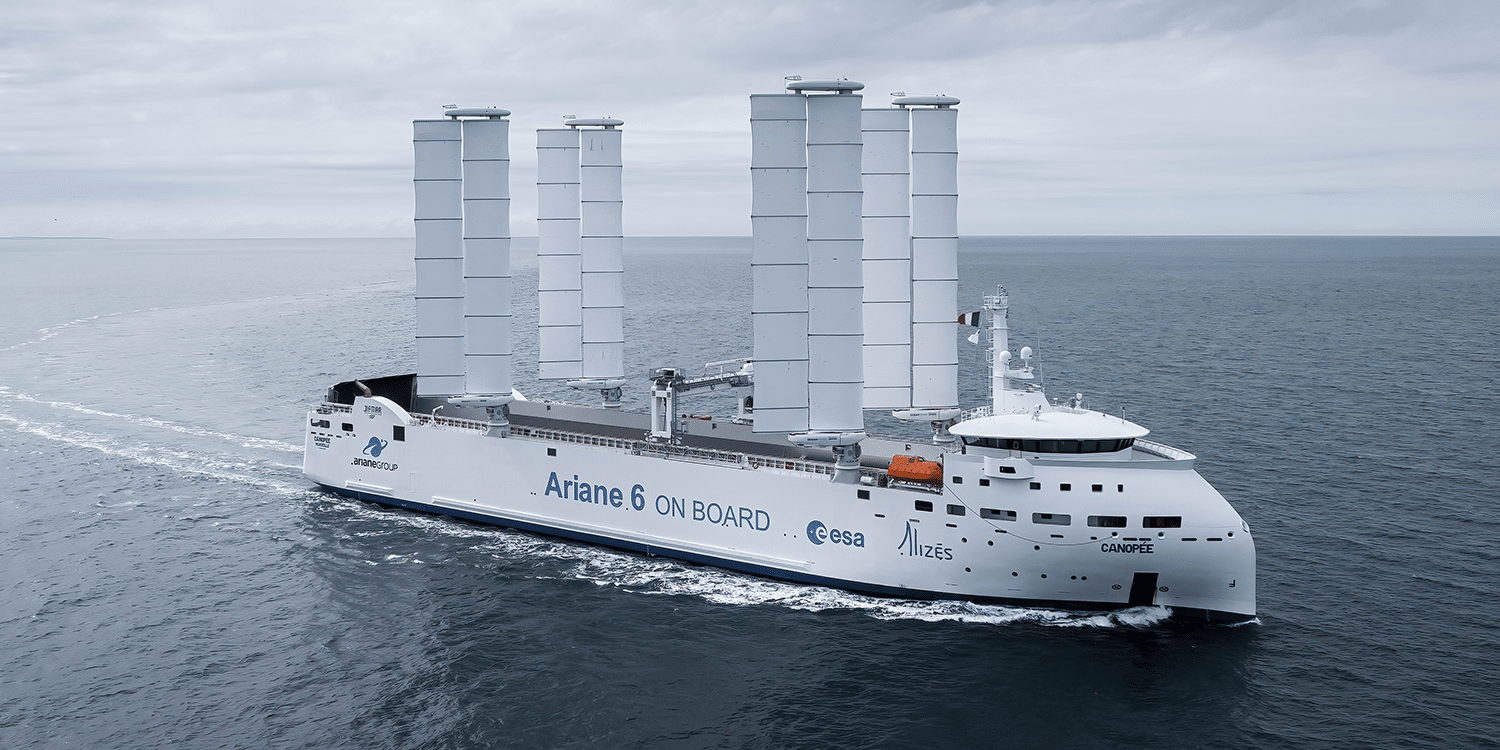

Canopée is a French sail-assited freighter ship.

Laid down in2019 and launched in 2022, it's designed specifically to transport elements of the Ariane 6 rocket from European ports to the Guiana Space Centre in Kourou, French Guyana in South America.

© Jifmar Group Library / Tom Van Oossanen

A new era of sailA key advantage of wind propulsion is that it can supplement, rather than compete with, other emissions-reduction efforts, such as alternative fuels, new propulsion systems and digital technologies.

While moving ahead with Wind Challenger, MOL is also leveraging digital solutions such as its DarWIN Project to improve fuel efficiency by streamlining operations, and the in-house Focus Project, which collects big data from around 170 vessels to optimise ship management.

The company has also established a subsidiary in the Philippines, EcoMol, to enhance operational efficiency through digital solutions.

In addition to streamlining operations to lower emissions, MOL is transitioning its fleet from heavy fuel oil to lower-carbon LNG and, eventually, carbon-neutral fuels such as biofuels.

Wind power will play an essential role in supporting these measures.

“It’s challenging to reach net-zero emissions solely with current alternative fuels,” says Hashimoto.

“As the availability of alternative fuels improves and prices eventually decrease, wind-propulsion solutions can help offset the costs of these new fuels in the long run.”

Links :

- FT : Charting a course for decarbonising global shipping

- Maritime Executive : Norsepower Installs Rotors on Gas Carrier as SHI Presents New Wind Concept / BV: Wind Propulsion Has Come of Age, But Needs Better Regulatory Clarity

- Miami Univ :‘Windfall’ technology to power cargo ships

- Fast Cie : The world’s largest wind-powered cargo ship just made its first delivery across the Atlantic

No comments:

Post a Comment